- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

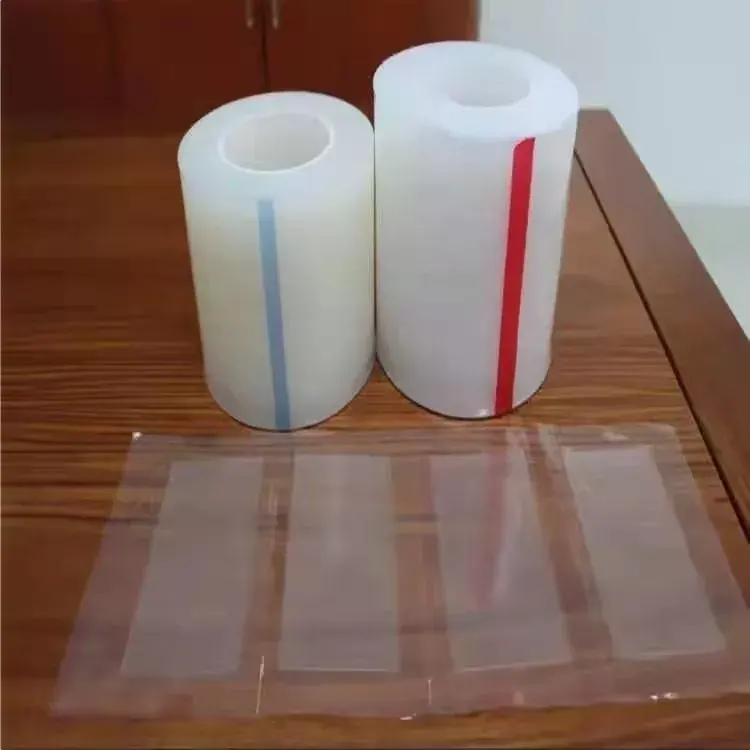

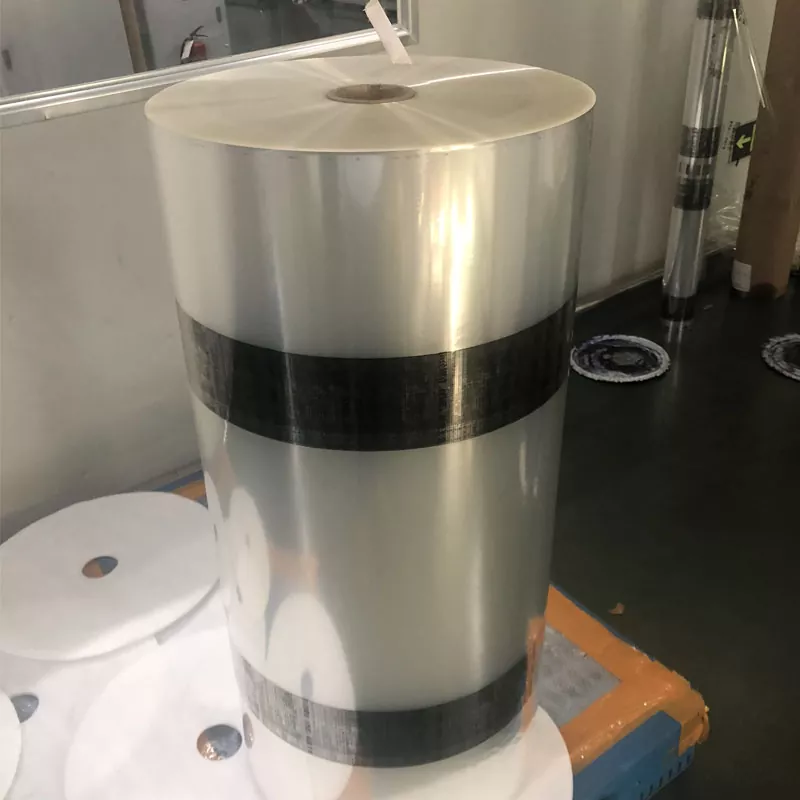

Acrylic Single Side Coated Film

Yongyuan is a leading China Acrylic Single Side Coated Film manufacturers, suppliers and exporter. It is suitable for the production and shipment protection of touch screens, lenses, panels, optical films, etc. in mobile electronic products.

Send Inquiry

As a professional high quality Acrylic Single Side Coated Film manufacturers, you can rest assured to buy Acrylic Single Side Coated Film from Yongyuan and we will offer you the best after-sale service and timely delivery. Acrylic, also known as PMMA or acrylic, comes from English acrylic (acrylic plastic). The chemical name is polymethyl methacrylate, which is an important plastic polymer material developed earlier. It has good transparency, chemical stability and weather resistance, easy to dye, easy to process, and beautiful appearance, so it is widely used Favored by the new material industry, it is also famous in the field of protective film. Acrylic has high transparency, soft light, and clear vision. Acrylic dyed with dyes has a good color development effect. It has a light transmittance comparable to glass, but its density is only half that of glass. In addition, it is not as fragile as glass, and even if broken, it will not form sharp fragments like glass, so acrylic glue is an ideal material for electronic product protection films.

In terms of processing, the characteristics of acrylic glue are also particularly good. Acrylic has good weather resistance, high surface hardness and surface gloss, and good high temperature performance. It can be thermoformed or machined. The wear resistance of acrylic is close to that of aluminum, good stability, and corrosion resistance to various chemicals, so it is also very conducive to mixing with other compounds during processing. Acrylic seems to be flammable but will not spontaneously combust, but acrylic glue is very viscous, and there will be glue residue after tearing off, while silicone will have no glue residue after tearing off. Put the protective film on the surface of the object to be pasted, and lightly tap it with your fingers. The one that sticks quickly without or with fewer bubbles is silica gel, and the one that sticks slowly and produces bubbles is acrylic oil glue. Generally speaking, the temperature resistance and stability of acrylic oil glue are worse than that of silica gel, but the anti-static piece is still made of acrylic. Silicone will cause silicon transfer and damage the product. For electronic products, this anti-static is very important. necessary. Acrylic protective film is mainly used for packaging high-gloss products and as a membrane switch, which is a cheap and easy-to-use film.

A PET protective film made of a transparent PET film as the base material and coated with a slightly sticky solvent-based acrylic adhesive. It is suitable for the production and shipment protection of touch screens, lenses, panels, optical films, etc. in mobile electronic products.

1. Acrylic Single Side Coated Film has suitable bonding strength and good retention for various pasted objects such as metal, plastic, glass, etc.

2. There are many types of stickiness, and the surface of the protective film is smooth and flat;

3. Good weather resistance, heat resistance, acid and alkali resistance.

Application field of Acrylic Single Side Coated Film

1. Surface protection during product transportation;

2. Die-cut protection and reposting of various metal films;

3. Protection of various plastic casings, keyboards and other plastic parts;

4. Die-cutting carrier, reposting and waste discharge of various films and tapes;

5. The different viscosities of the protective film can be used as a support carrier for foam die-cutting with different thicknesses;

6. Temporary transfer and fixation of electronic products.