- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

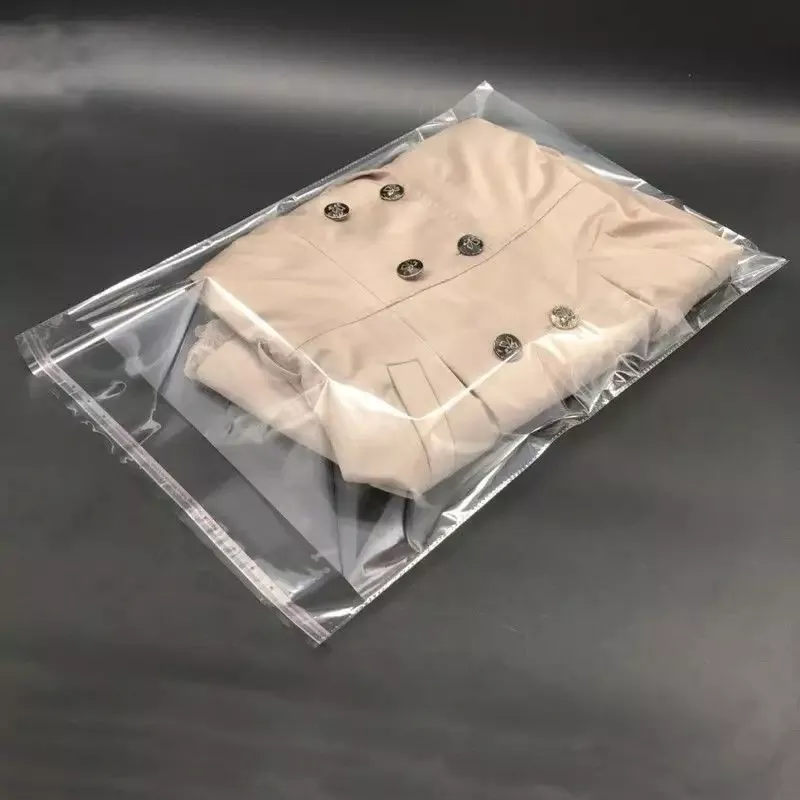

Opp Packaging Film

As the professional manufacturers, Yongyuan would like to provide you OPP Packaging Film. And we will offer you the best after-sale service and timely delivery. After corona treatment, OPP film has good printing adaptability, and can be overprinted to obtain exquisite appearance effects, so it is often used as the surface layer material of composite films.

Send Inquiry

As the professional manufacturers, Yongyuan would like to provide you OPP Packaging Film with the best after-sale service and timely delivery. Opp Packaging Film is a type of plastic film that is widely used in packaging applications. Opp stands for Oriented Polypropylene, which means that the film is made from a type of plastic material that is stretched and oriented in a specific direction during the manufacturing process. The film is commonly used in the food and beverage industry, where it is used to wrap products such as bread, chocolate, and confectionery items. It is also used for packaging non-food items such as CDs, DVDs, and other small consumer goods.

Characteristics of Opp packaging film

OPP protective film is based on OPP, and is mainly used for surface protection during product transportation; die-cutting protection, transfer and protection of various metals, films, and tapes; protection of various plastic casings, keyboards and other plastic parts.

The surface energy of OPP Wrapping Film is low, and corona treatment is required before gluing or printing. After corona treatment, OPP film has good printing adaptability, and can be overprinted to obtain exquisite appearance effects, so it is often used as the surface layer material of composite films.

1. The film is available in a variety of colors and designs, which makes it ideal for creating attractive packaging that can stand out on store shelves.

2.The film is designed to create a barrier that prevents these external factors from reaching the product, thus ensuring that the product remains fresh and in good condition.

3. Opp packaging Film is known for its excellent tensile strength, which means that it can withstand high levels of stress without breaking or tearing. This makes it an ideal material for packaging applications where the products are exposed to various forms of stress during transport and handling.

4.The film is designed to be transparent, which means that the product inside can be easily seen by the consumer. This is important in the food and beverage industry, where consumers need to be able to see the product before making a purchase.

5. The film can be easily sealed using heat, which makes it a convenient and cost-effective material for packaging applications. The heat-sealing process creates a tight seal that ensures that the product remains protected from external factors.

6.It is also resistant to punctures and tears, which means that it can withstand rough handling during transport and storage. This makes it a reliable material for packaging applications where the products are exposed to various forms of stress.